⸻

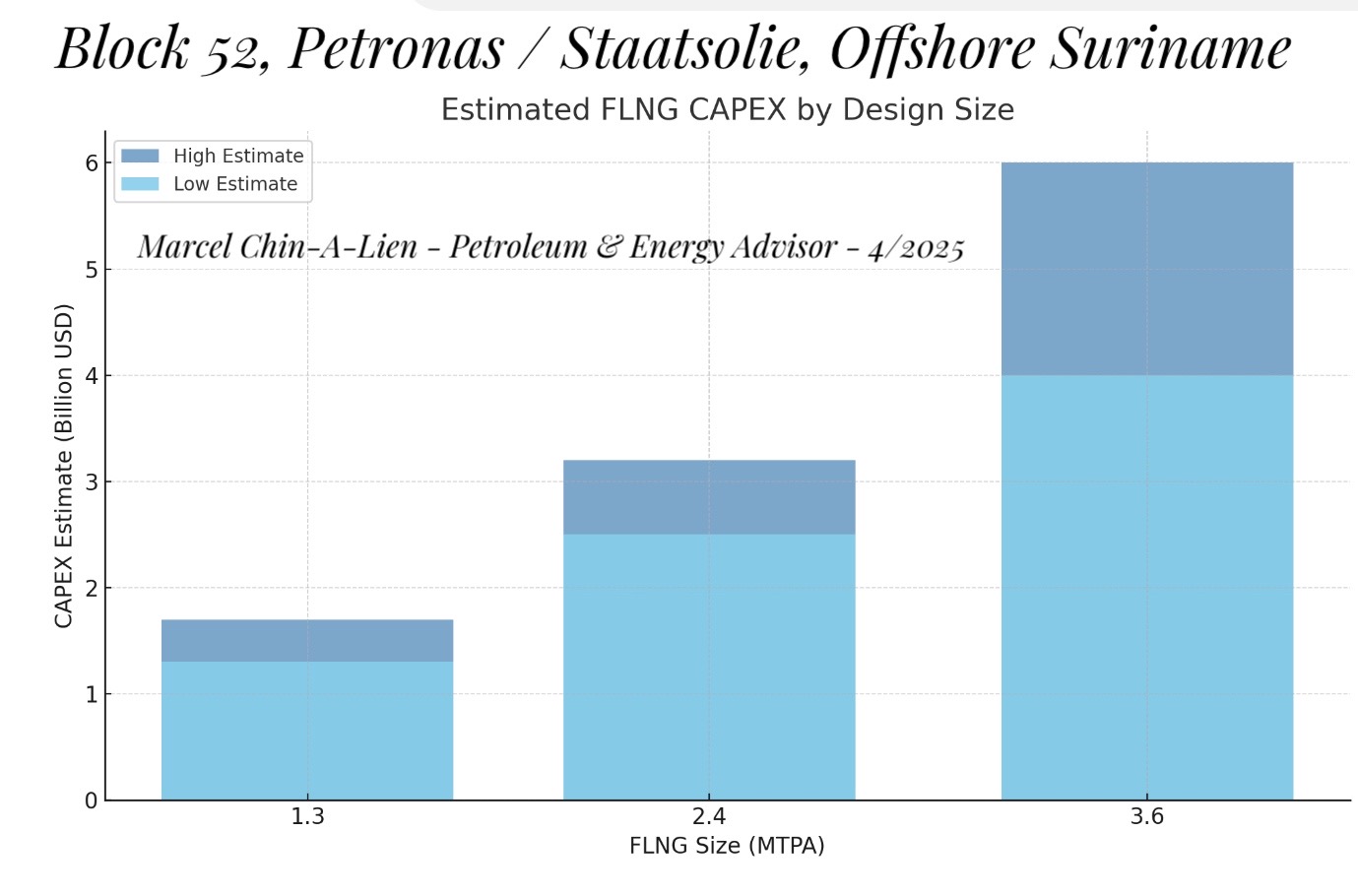

Estimated FLNG CAPEX per Design Size

| FLNG Size (MTPA) | CAPEX Estimate (USD) | Cost per Tonne (USD/MTPA) | Notes |

| 1.3 MTPA | $1.3 – $1.7 billion | $1,000 – $1,300 | Based on Tango FLNG & newer small-scale builds |

| 2.4 MTPA | $2.5 – $3.2 billion | ~$1,050 – $1,330 | Mid-size, often modular; Chinese shipyards competitive |

| 3.6 MTPA | $4.0 – $6.0 billion | ~$1,100 – $1,600 | Full-scale, like Coral South FLNG, Prelude FLNG was higher due to complexity |

Key Cost Drivers

- Engineering complexity: Larger MTPA requires more onboard processing (e.g., gas pretreatment, NGL extraction).

- Mooring & offloading systems: Bigger units often need turret mooring, tandem offloading.

- Shipyard location: Chinese and Korean yards offer differing cost/time tradeoffs.

- Local content and logistics: Distance from shore, water depth, infrastructure all matter.

- Contractor strategy: EPC lump-sum vs modular fabrication significantly affects price.

FLNG project costs scale significantly with size and complexity.

This is my estimated CAPEX (Capital Expenditure) range, and related Block 52, Petronas, FID expected in 2026.

For new-build FLNG facilities of 1.3, 2.4, and 3.6 MTPA, based on industry benchmarks and recent project data (e.g., Coral South, Prelude, Tango FLNG, and recent Chinese builds).